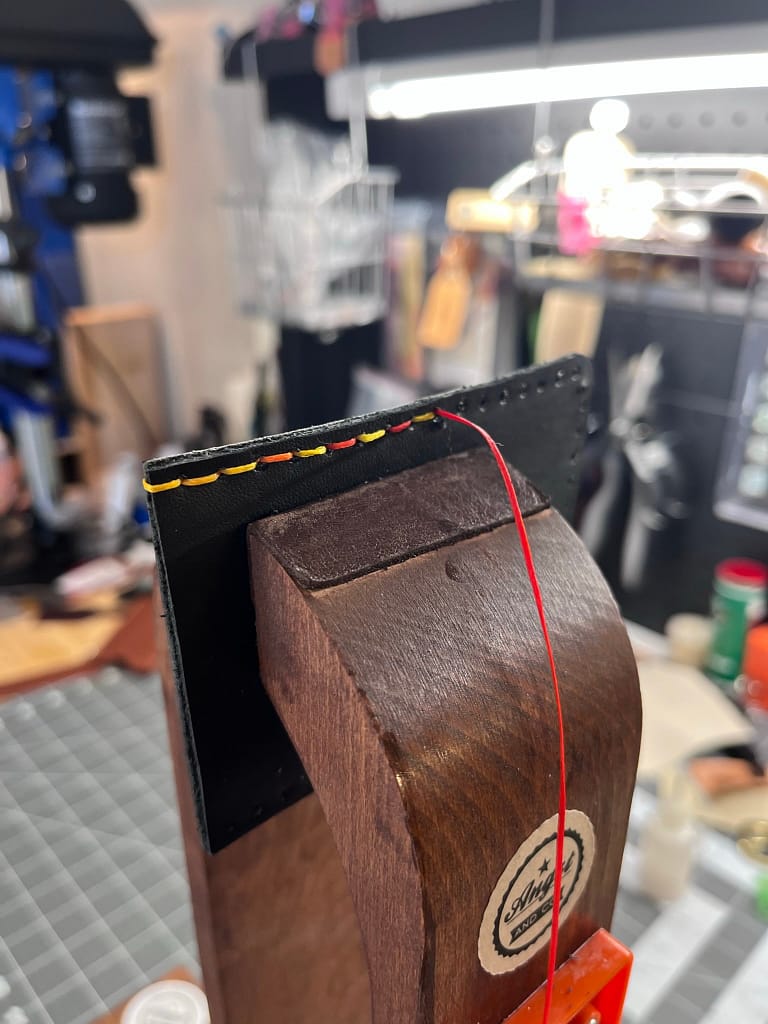

Saddle Stitching is the classic way of hand stitching leather. It is very durable and can last a lifetime when done correctly. What makes saddle stitching so strong is that it uses a running stitch. You start by threading a single thread on each end. Make a complete loop through each stitch hole, essentially making a figure 8 pattern the entire length of the line. This means that even if one loop breaks, it only affects that one stitch, as opposed to the machine stitch which can begin to unravel further down the line.

Another benefit of saddle stitching leather is that you can go with a thicker thread than in a machine. I prefer the look of the heavier thread as it looks more rugged, which is part of my brand. I especially like how it looks on my Classic Bifold Wallets.

The durability of saddle stitching comes at a cost, though. What takes a machine minutes, can take hours for an experienced leather crafter to do by hand. To hand stitch an item together, the leather worker must cut the leather to size, mark stitching holes and then manually punch each hole. A sewing machine pierces the hole and stitches at the same time. This difference is what causes a price gap between completely handmade leather goods and machine stitched goods. The reward for the time and labour is a more durable stitch, possibly even the strongest stitch we know of.

In my opinion, I think saddle stitching is better than machine stitching when extreme strength and longevity is the desired outcome. Let me know what you think? Contact me here!